Water Tight Technologies, LLC.

RUBBERALL®

ADDRESSING THE NEEDS OF

LOCAL ROOFING CONTRACTORS

CONVENIENCE

- Local availability is critical to your productivity.

- Smaller roll sizes make transportation and loading the roof top easier and safer.

QUALITY

- RUBBERALL® membrane (EPDM) is the longest lasting low-slope roofing product available for residential and light commercial projects.

- Contractors and home owners have satisfaction knowing that RUBBERALL® membrane and accessory technology has stood the test on the roof tops around the world for more than 40 years.

SUPPORT

- Estimating guide, installation manual and video are available to assist the contractor on roofing projects.

- Technical hotline is available to assist the contractor with questions.

- RUBBERALL® membrane warranty is unsurpassed in the industry: 30 years for .060" and 20 years for .045" membrane.

RUBBERALL® CONTRACTORS ARE OUR

"PARTNERS IN QUALITY"

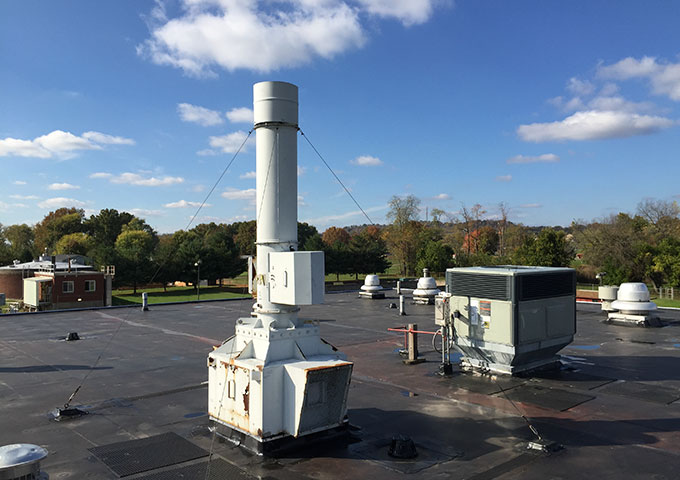

As roofing and and landscape contractors,

you encounter projects like these everyday!

Ask your local lumberyard to carry the best...

© Copyright 2000-2023, Water Tight Technologies®. RUBBERALL®, BRITE-n-EZ® and Water Tight Technologies® are registered trademarks of Water Tight Technologies LLC. All Rights Reserved.

“E-ZEE” ROLL™ is a trade mark of Water Tight Technologies, all rights reserved.